D-Cell Battery Management System

The D-Cell Battery is a general-purpose energy storage module with a fully integrated protection system, delivered as a standalone 1kWh unit (13V / 80Ah). Each battery features a built-in Battery Management System (BMS) designed specifically for Lithium-Titanate (LTO) chemistry.

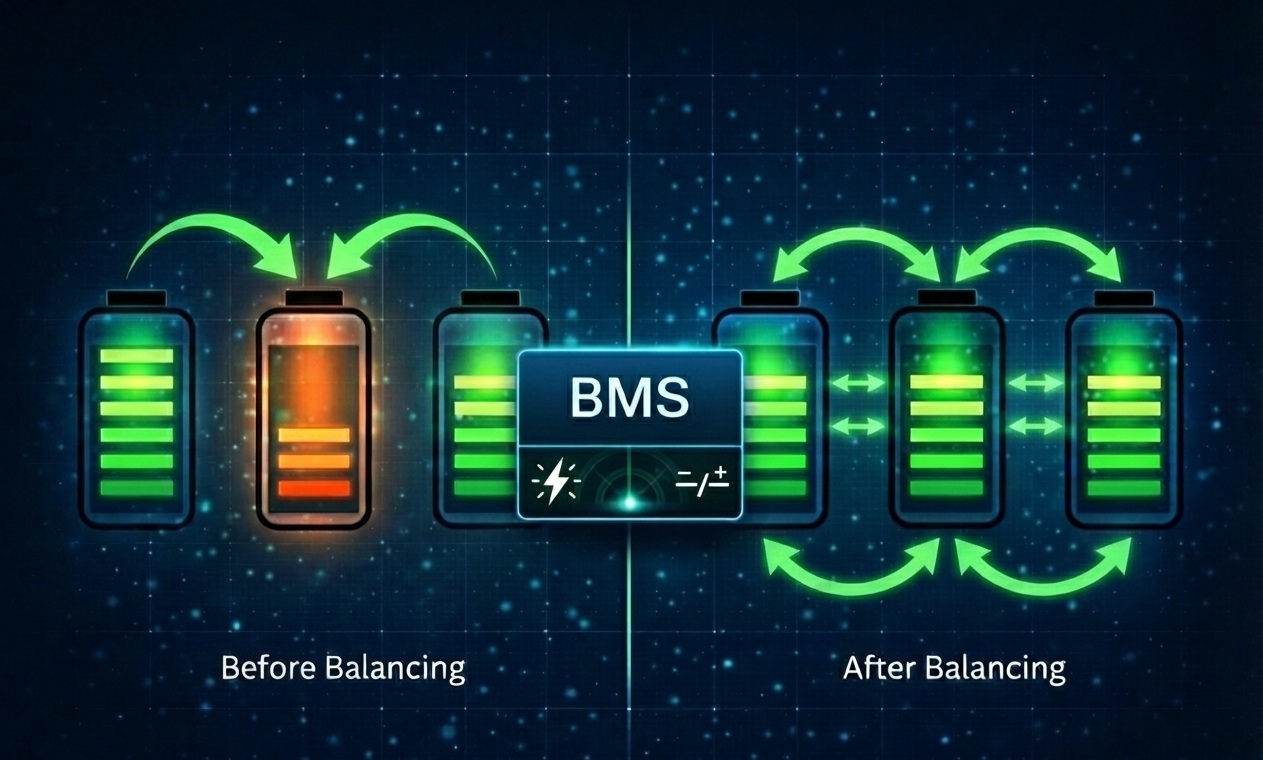

Cell Management & Balancing

Intelligent active and passive balancing ensures uniform cell behavior across all system configurations.

- Active cell balancing within each battery module

- Passive balancing for 12V / 24V / 36V / 48V systems

Electrical Protection Layers

Multi-layer hardware and software protection safeguards the system under all electrical fault conditions.

- Dual-level hardware short-circuit protection

- Software-based RMS overcurrent protection

- Dual-level hardware overcurrent & overvoltage protection

- Reverse polarity protection

Voltage & Surge Safety

Designed to handle voltage extremes and transient events without compromising battery health.

- Low-voltage protection (< 12V)

- Overcharge protection (> 15V)

- Transient surge protection

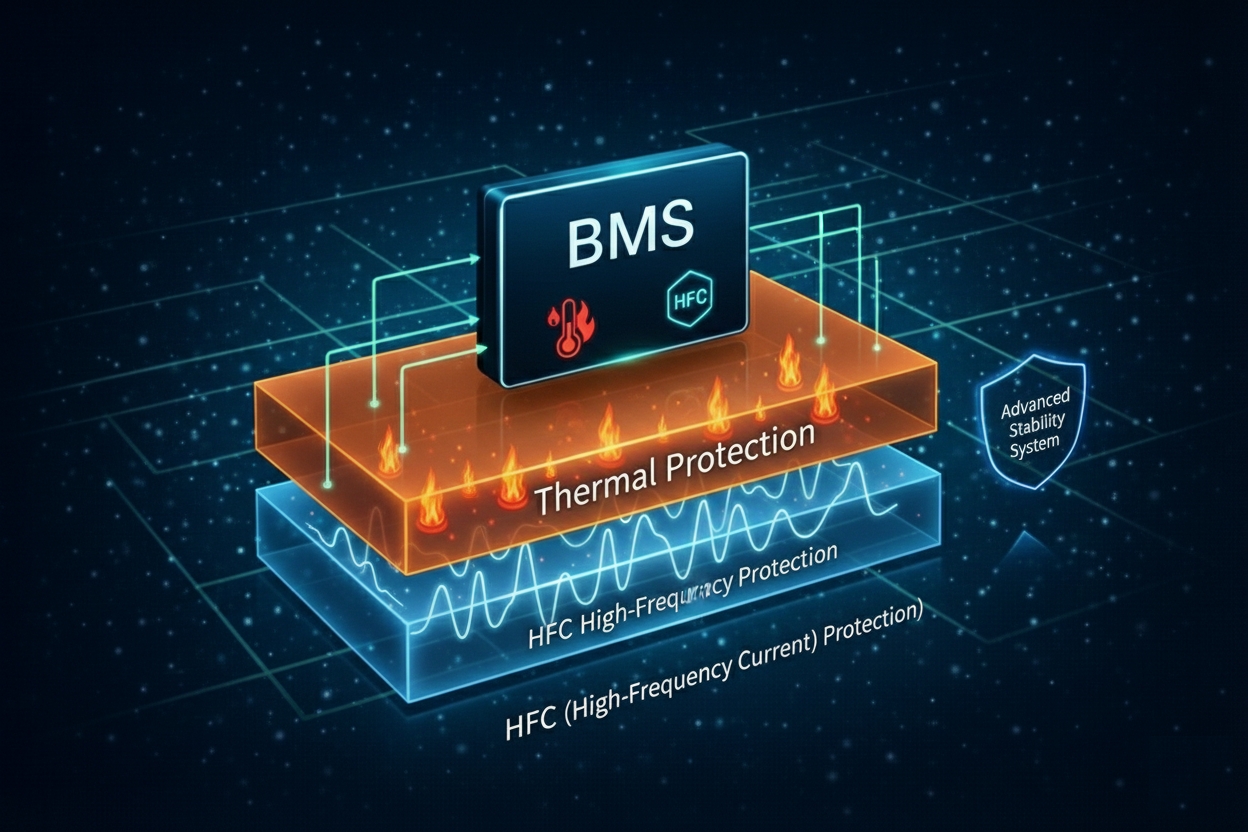

Thermal & High-Frequency Protection

Advanced thermal and high-frequency current monitoring ensures long-term stability even under harsh operating conditions.

- Thermal protection

- High-Frequency Current (HFC) protection

BMS Services & System Intelligence

An integrated microcontroller-based Battery Management System (BMS) provides advanced communication, diagnostics, logging, and energy management features for professional operation and long-term reliability.

Communication & Service Access

The battery is designed as a general-purpose energy storage system with modern microcontroller-based service capabilities. It supports communication, diagnostics, configuration, and firmware updates without requiring disassembly.

For service and configuration purposes, the system uses a dedicated infrared (IR) communication interface. The IR module connects to a PC via USB and communicates with the battery from a short distance (~10cm), similar to a TV remote control.

A dedicated optical port is integrated into the battery housing. The mechanical design ensures reliable optical coupling while physically blocking interference between neighboring batteries— an important safety feature in large-scale installations.

Through the IR interface, each battery can be individually addressed by its unique ID, queried for status information, controlled, and updated with new firmware versions.

Event Logging & Diagnostics

The BMS continuously records operational events to support fault analysis, maintenance, and long-term system diagnostics.

In active operation, events are logged at one-second intervals. In low-power sleep mode, logging continues at extended intervals while maintaining periodic internal checks.

Each log entry contains timestamped information including voltage, current, temperature readings, operating states, status flags, and the most recent critical events.

The internal event log is designed for long-term operation and automatically overwrites the oldest entries when full. Logged data can be retrieved via the IR interface over a selectable time range. In forensic or failure-analysis scenarios, the data can also be extracted directly from internal storage.

Status Monitoring & BLE Mesh Communication

For everyday operation and system monitoring, the battery supports BLE Mesh communication. This channel is optimized for safe, low-power, and scalable status reporting.

The BLE interface provides real-time information such as state of charge (SOC), current, cell imbalance indicators, operating state, and system flags. Communication is intentionally limited to one-way data transmission for enhanced safety.

Multiple batteries can be monitored individually or as logical groups, with aggregated values available for system-level overview. Data can be displayed locally or forwarded to remote monitoring systems via gateways or servers.

Professional Maintenance & Load Testing

For large installations and safety-critical systems, the BMS supports professional maintenance and supervision via an IR-RS485 communication architecture.

Multiple IR modules can be connected on an RS485 bus, allowing centralized supervision of dozens or even hundreds of batteries. This architecture is electrically isolated and remains safe even under extreme potential differences.

The system enables remote diagnostics, contact quality assessment, and automated load self-tests without physical battery removal. During self-test sequences, batteries are tested sequentially to avoid system downtime.

In the event of a detected anomaly, the system precisely identifies the affected battery by serial number, allowing targeted replacement without shutting down the entire installation.

Energy Saving & Intelligent Sleep Mode

To minimize self-discharge during long periods of inactivity, the battery features an intelligent low-power sleep mode. This is especially important for seasonal or standby applications such as marine, agricultural, or backup power systems.

The BMS automatically enters sleep mode when current, current variation, and state-of-charge conditions remain within defined limits for a specified duration. While asleep, the system performs periodic wake-ups for health checks and event logging.

Wake-up can be triggered by charging or discharging currents, rapid current changes, IR commands, system resets, or an integrated magnetic sensor—allowing safe and reliable activation even without electrical contact.